Technical advice

Benefits of chrome plating on plastic

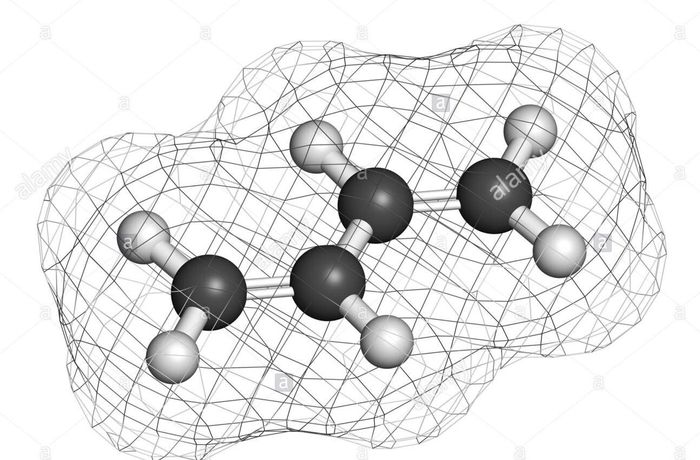

Why ABS is the most widely used plastic material:

• Low cost

• Low coefficient of thermal expansion

• Easily moldable

• Good adhesion of metal plating

Slide title

Write your caption hereButton

Preparing the piece:

- The injection points should preferably be located in the less visible areas of the parts.

- It is recommended to inspect the mould surface to avoid dull areas or noticeable blemishes.

- Humidify the material for the correct amount of time and at the correct temperatures to prevent lifting and bubbles during treatment.

- Ensure adequate melting temperature to avoid internal stresses.

- Ensure proper mould temperature to prevent too rapid cooling of the material in contact with the mould walls.

- The tolerance of the parts must take into account the final thickness of the galvanic deposit.

- Absolutely avoid the use of silicone-based release agents.

Equipment and packaging:

Appropriate equipment (frames) will serve as support for the pieces throughout the chrome plating process:

Processing

They are necessary to:

- Prevent deformation of the piece

- Prevent detachment of the pieces during the process,

- Allow the correct amount of current to pass to obtain the correct deposit.

- It is essential to use suitable packaging for both the raw material and the chrome-plated material to achieve an optimal aesthetic result.

Slide title

Write your caption hereButton

CONTACT DETAILS

+39 0331 820001

BUSINESS HOURS

- Mon - Fri

- -

- Sat - Sun

- Closed